Committed to The Research and Development of Stainless Steel Products.

With twenty-six years of manufacturing experience.

About Us Our Product

Water pump castings refer to various parts used in water pumps, which are mainly manufactured through casting processes. As a mechanical equipment used to transport liquids and provide pressure, the performance and reliability of water pumps are directly related to the operating efficiency and safety of industry, agriculture, construction and other fields. As an important part of the water pump, w...

More Product

Valve castings refer to valve parts made of metal materials through a casting process and used to control fluid flow. Valves play a vital role in the industry, energy, chemical industry, water treatment, and other fields, and valve castings, as the core component of valves, play a key role in ensuring the normal operation of the system, fluid control, and preventing leakage The manufacturing proce...

More Product

Impeller casting is a part used in manufacturing liquid or gas pumps, fans, and other rotating machinery. The impeller is a rotating component with a specific geometric shape. Its main function is to generate or transfer the kinetic energy of the fluid through rotation. Impeller castings are usually cast from metal or other alloy materials and have high strength and wear resistance. Impeller cast...

More Product

Pipe castings refer to components used to connect and support pipeline systems. Common pipe castings include elbows, flanges, joints, pipe caps, etc. Pipe castings are usually made of cast iron, cast steel, stainless steel, and other materials, and have high strength and corrosion resistance. The main function of pipe castings is to realize the connection, diversion, and branching of the pipeline...

More Product

Mechanical accessories refer to various parts and components used for the assembly and operation of mechanical equipment. They usually cooperate with the main mechanical structure to complete specific functions or play roles such as support, fixation, transmission, and sealing. There are many types of mechanical accessories. Common ones include shafts, bearings, gears, chains, couplings, screws, ...

More Product

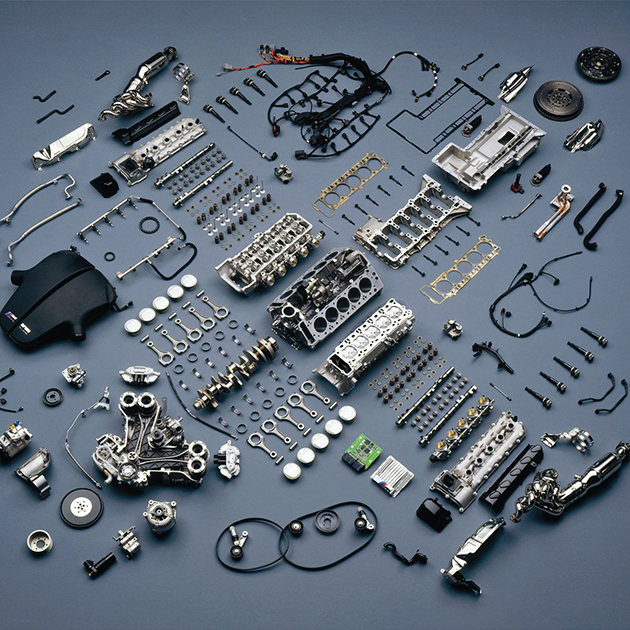

Auto parts castings are an indispensable and important part of the automotive manufacturing field. They are made through casting processes and are widely used in many automotive parts such as engines, chassis, and transmission systems. Auto parts castings can be divided into many types, depending on their uses and locations, including engine castings, chassis castings, transmission system castings...

More Product

Train accessories castings refer to various parts used in railway transportation systems. These parts are manufactured through casting processes and are used to support and maintain the normal operation of trains. As an important means of transportation, the normal operation of the railway system relies on a variety of high-quality, durable parts and castings. These parts play a vital role in ensu...

More Product

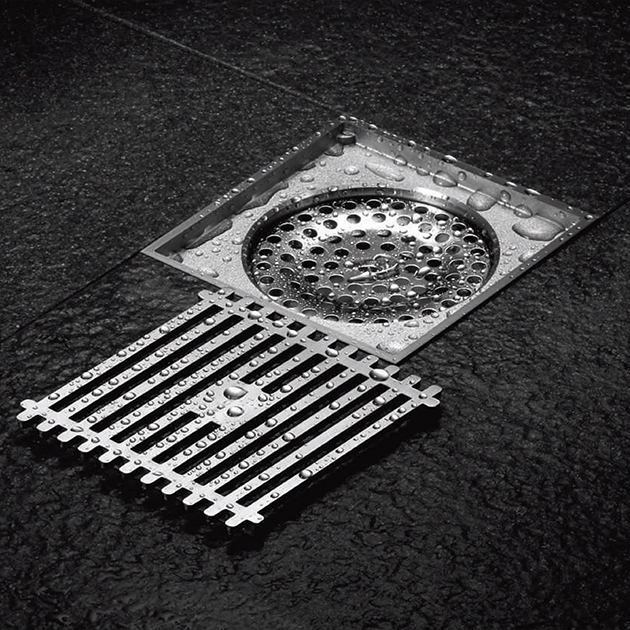

Architectural hardware castings are a vital component in construction projects. They provide necessary support, connections and decoration for building structures. These castings are typically made from metallic materials and are machined through a casting process to meet the specific needs of a construction project. These components are often used in building structures, doors, windows, railings,...

More Product

Lock accessories castings refer to the parts of locks made by casting technology, usually made of metal alloy materials. These castings can include lock cylinders, lock shells, lock bolts, keyhole covers and other key components that make up the lock. The design and manufacturing of lock accessory castings need to take into account factors such as structural strength, corrosion resistance, and pro...

More Product

Since its establishment 26 years ago, the company has focused on the R&D and production of high-quality stainless steel products.

We have our own testing laboratory and testing equipment to ensure high product quality.

In the Stainless Steel Casting industry, Intergranular Corrosion is a critical challenge that threatens the long-term safety of industrial components. For specialized Stainless Steel Elbow Reducer Cas...

In the Stainless Steel Casting process, Porosity and Slag Inclusion represent two of the most critical quality challenges affecting structural integrity and corrosion resistance. For high-precision co...

In the production of Stainless Steel Control Valve Castings, Subsurface Pinholes represent a particularly insidious defect. Unlike surface porosity, these tiny voids are trapped just 1 mm to 3 mm bene...